Chocolate Fresh from the Source

UNIQUE CACAO VARIETALS

EXPERT FARMERS & CHOCOLATE MAKERS

RICH VOLCANIC SOIL

ANCIENT TRADITION

In keeping with our roots, Sibö Chocolate never overprocesses its chocolate. We adhere to a time-honored tradition of grinding and conching cacao beans, aspiring to preserve the incredible flavor of our cacao in every bar and hand-made confection. We find inspiration in historical recipes, cultural traditions and fresh, local ingredients. Simple, natural, and an enduring source of energy, right from the source.

We trade directly with expert farmers who provide our professional chocolate makers with only the best fine-flavor beans to produce chocolate that is uniquely Costa Rican.

Visit the Factory

Expert Farmers

Sibö partner farms are experts at fermenting and drying cacao to unlock its flavor potential. Our job at Sibö is to further develop that flavor, bringing out the best in those beans, and craft a chocolate bar that will hopefully make you stop in your tracks.

Unique Cacao Varietals

Costa Rica is one of the few countries that produces exclusively fine-flavor cacao, a superior category of beans representing only 12% of the world cocoa market. That means that our chocolate has a rich and balanced base of chocolate flavor along with hints of more complex flavor notes, such as fruit, caramel, roasted coffee and nuts. While some of the flavor magic lies in the rare genetics of our country’s cacao, the quality of our chocolate depends on what happens after the beans are harvested.

Terroir

For thousands of years, ancient lava flows and volcanic ash have fed these lands with nutrients and minerals to form a rare type of soil called Andisol. This rich earth and year-round warm, tropical weather contribute to our cacao’s unique terroir. From region to region, and even from farm to farm, you’ll find surprising flavor notes that distinguish our Costa Rican chocolates from other cacao producing countries around the world.

Ancient Tradition

Long before the Europeans transformed chocolate into what we know today, peoples native to these lands were preparing a pungent elixir called xocolatl (meaning “bitter water” in the Nahua language). This stimulating libation was made by grinding dry fermented cacao beans into an unctuous paste and melting it into water, together with fragrant vanilla beans, dried chili peppers, and pulverized maize. The drink was a source of energy served on special occasions, often reserved for warriors before battle.

Today, indigenous Costa Ricans still prepare their own chocolate, plucking ripe cacao pods from wild trees planted by their elders. These trees and the forest at large are considered a most precious gift from Father Nature, also known as Sibö. For many, the process of making chocolate remains unchanged, fermenting and drying the beans under the sun before grinding them on a warm stone slab and blending the brown paste into water. Special occasions are still often marked with chocolate in Costa Rica’s indigenous communities and some cultures continue to use chocolate in funerary rituals.

Professional Chocolate Makers

Making chocolate is a labor of love. From farm to table, there are nine steps in getting a delicious chocolate bar to you—and each one is critical. A delicious chocolate depends on great cacao beans, but also how those beans are processed and how the chocolate is made.

Harvesting, Fermentation & Drying

Cacao pods, which mature at different rates, have to be harvested by hand at just the right time. Each pod is cracked opened by hand and the fresh beans have to be scooped out and placed in fermentation boxes with care. For the fermentation process to yield the best results, the right temperatures and time for aerobic and anaerobic phases are required. Drying the beans is also an essential step—too slow could lead to moldy beans, too fast could seal in some moisture.

Roasting & Winnowing

Assuming all this has been done right, the roasting process is critical. Reaching just the right temperature for just the right time will enhance all those great flavors in the bean without masking them behind a high roast. Winnowing follows, which requires removing as much of the shell as possible without losing pieces of the bean (cocoa nibs). This is an imperfect process.

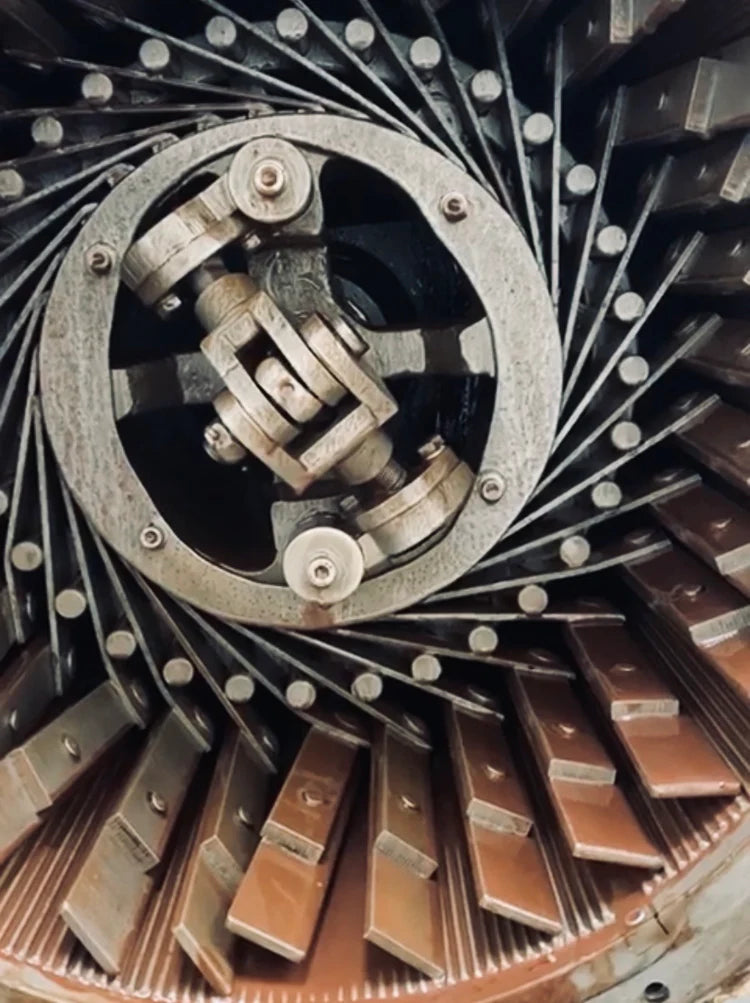

Grinding & Conching

Special equipment is used to achieve the right texture and balance of flavor during these steps. This part of the process is a big moment for defining the overall quality of the chocolate. The goal is to refine the cacao pieces and sugar until the paste feels smooth and silky on the tongue, all while reducing bitterness and astringency. But that can be hard to accomplish without also losing some of the pleasant acidity. Too much conching and the chocolate will fall flat.

Tempering & Molding

Finally, the tempering process is crucial to giving the chocolate all the characteristics that we love: the shine, the snap and the perfect melt in your mouth.

Every bar of Sibö chocolate adheres to the highest standards of quality in order to deliver excellent chocolate every time. While we celebrate the unique flavors developed in each batch we make, we take care in monitoring all steps in the chocolate making process, in order to guarantee outstanding flavor each and every year.

Quality Assurance Training

SIBÖ’S quality assurance staff has completed exhaustive training as auditors in Best Manufacturing Practices for food safety with Costa Rica’s National Learning Institute (INA). All Sibö Chocolate employees hold certificates in food handling and adhere to strict guidelines to guarantee food safety and traceability.

Members of our staff have also completed coursework with international specialists through Costa Rica’s Universidad Nacional, to form part of an official panel of expert cacao tasters for the country.